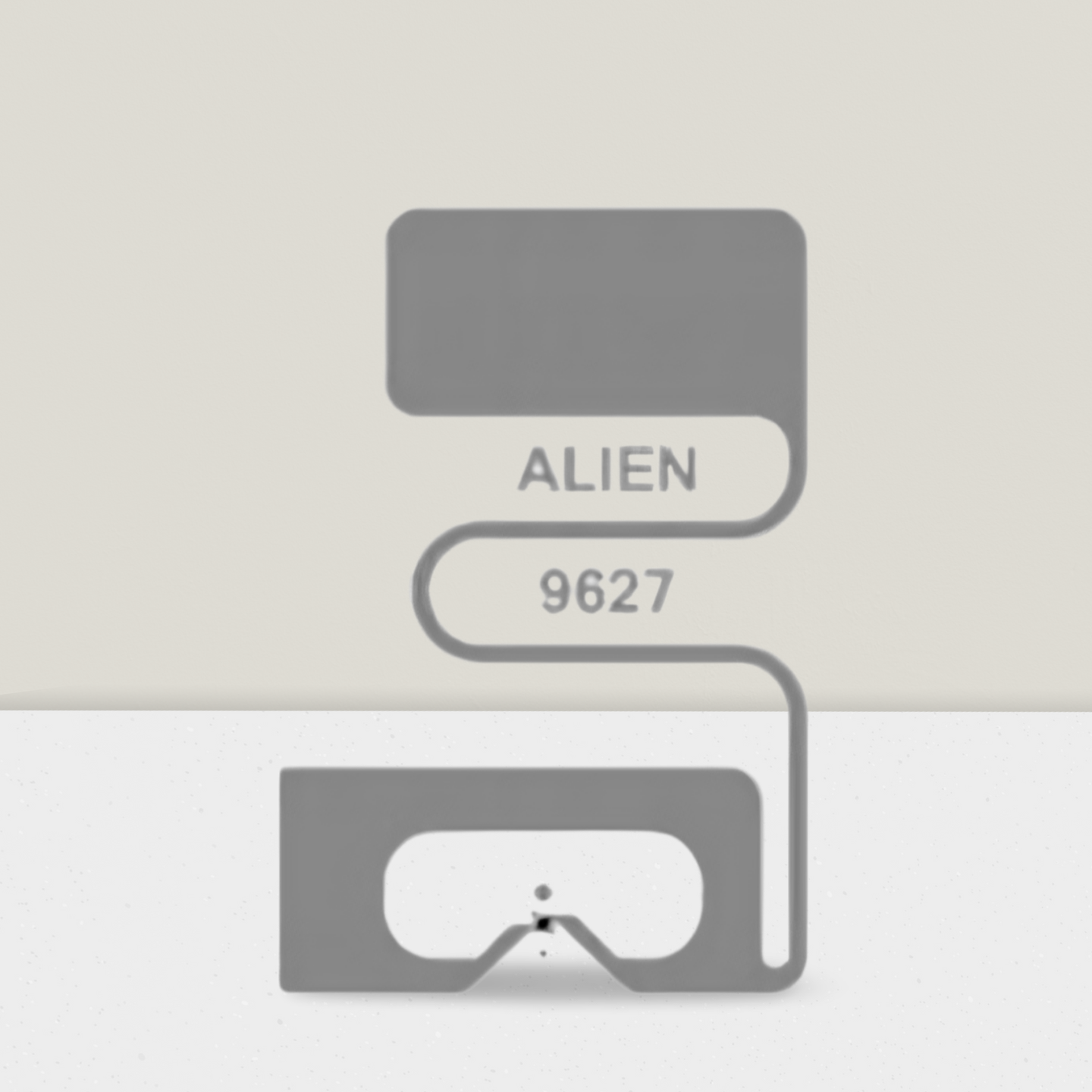

RFID inlays are the core components of RFID tags and labels. They consist of an RFID chip and an antenna, which are embedded in a substrate. RFID inlays can be categorized into two main types: wet inlays and dry inlays.

RFID wet inlays are created by attaching the RFID chip and antenna to a substrate using a wet adhesive, such as glue or adhesive film. Wet inlays have a moist adhesive layer, as they are not fully dried during the manufacturing process. This makes them ideal for applications where the inlay needs to be applied to a variety of surfaces, including porous materials such as paper and cardboard.

Wet inlays are typically more durable and resistant to harsh environmental conditions than dry inlays. This is because they are often protected by additional processing steps, such as lamination or encapsulation. Wet inlays are also more resistant to chemicals and abrasion.

RFID dry inlays are created by placing the RFID chip and antenna onto a substrate using a dry adhesive. The adhesive dries out, leaving the inlay ready for further processing or attachment to an object or surface.

Dry inlays are typically thinner and more flexible than wet inlays. This makes them suitable for applications where the inlay needs to conform to various surfaces, such as labels or tags. Dry inlays are also easier to handle and apply than wet inlays.

However, dry inlays may be less resistant to harsh environmental conditions compared to wet inlays. They may also be less durable and more susceptible to chemicals and abrasion.

RFID wet inlays are commonly used in applications that require higher durability and resistance to harsh conditions, such as:

Industrial asset tracking

Logistics and supply chain management

Automotive manufacturing

Healthcare

Food and beverage processing

RFID dry inlays are commonly used in applications such as:

Retail item tagging

Inventory management

Access control

Library and document management

Event ticketing

Choosing the Right RFID Inlay for Your Application

When buy an RFID inlay, it is important to consider the following factors:

The type of environment in which the inlay will be used

The required durability and performance of the inlay

The type of surface to which the inlay will be applied

The budget

If you need an RFID inlay that is durable and resistant to harsh environmental conditions, then a wet inlay is the best choice. If you need an inlay that is thin and flexible, then a dry inlay is the best choice.

Conclusion

RFID wet inlays and RFID dry inlays each have their own unique advantages and disadvantages. It is important to choose the right type of inlay for your specific application. If you are unsure which type of inlay is right for you, then it is a good idea to consult with an RFID specialist.

255.jpg)

DO RFID tag manufacturer produce various NFC tags. The ntag215 NFC tags are small, inexpensive and portable, it with a tiny ntag215 chip and antenna operate at 13.56 MHz.

More >>

Best Metal business card with qr code can be used in various industries and applications. For instance, hotels can add QR codes on their keycards that direct guests to a website where they can make changes to their reservation.

More >>